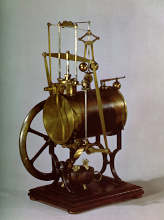

44 x 17.5 x 26

Brass and wood

CAT. 1851 : 56.G.II

Modêlo da machina de vapôr d'alta pressaõ de Trewtch.

A model of Trewtch's high pressure steam machine.

The steam engine was without doubt one of the most influential inventions in the development of industry and civilization.

One of the first machines constructed with the purpose of using steam pressure to make a body move was the Spiritalia, constructed by Heron, in Alexandria in 1 BC. This machine was composed of a rotating aeolipile in the shape of a hollow sphere, from which two diametrically opposed curved tubes lead like a hydraulic tourniquet. The sphere could turn around a horizontal axle passing through its centre. These pieces of apparatus, initially constructed without any concern for practical application, but as an instrument of recreation, would nevertheless come to be the forerunners of gigantic machines constructed in the 18th and 19th centuries, which played a unique role in technological revolution.

Following Papin's studies, various machines emerged that capitalized on the movement of a piston inside a cylinder, moved by water vapour under pressure.

In the 18th century some machines were developed in which steam was condensed by the direct injection of a jet of cold water inside the cylinder when it was under pressure. Initially, simple mechanisms were developed in which the steam, on entering the interior of the cylinder, exerted strong pressure on the piston making it move in a certain direction. The steam entered through a valve that connected with the container of boiling water. When the piston reached the end of its course inside the cylinder, this valve was automatically closed, and then the cold water was injected. To do this, a second valve was opened, ensuring a rapid reduction of pressure inside the cylinder. With the condensation of the steam, the piston was obliged to move in the opposite direction. In the first machines constructed, this return movement of the machine was simply caused by the action of atmospheric pressure. This type of machine was designated a machine of simple effect. As a consequence of the difference between the two agents that acted on each side of the piston- steam under pressure and atmospheric pressure- an asymmetry in the characteristics of the movement in the two directions resulted, being faster and more efficient when the steam was admitted into the cylinder whereas the return, under atmospheric pressure, was slower.

In order to resolve this problem, systems were developed where the steam entered alternately into one side and then the other side of the piston. To admit the steam in this way, valves which opened alternately were used, permitting entry of the steam on only one side of the piston at a time. While the steam entered one of the parts of the cylinder that were divided by the piston, cold water was injected into the other causing condensation of the steam. The resultant liquid was collected in its own receptacle and periodically withdrawn. This type of machine was known as being of double effect.

In 1769 Watt developed a new type of machine in which the steam was freed into the atmosphere through the opening of a valve, avoiding the disadvantages of the steam condensation through the action of a jet of cold water. The opening and closing of the escape valve was made through a complex system of gears, controlled by an axle that moved with the piston. Various mechanisms were developed for this and installed in a distribution box which allowed the steam to escape alternately from each one of the sectors defined by the piston inside the cylinder.

Two conical pendulums, made of two spheres that moved in a circular trajectory on a horizontal plane, were used to activate the second valve in the machine's escape system, allowing the flow of steam to be regulated, and thus the velocity of the machine. This mechanism is known as Watt's regulator, in homage to its inventor (instrument 61).

Daguin, Pierre-Adolphe, Traité Élémentaire de Physique Théorique e Expérimentale, Paris, 1878, § 1195 and 1208.